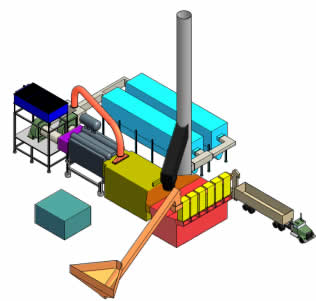

The ROC is a rapid organic converter. Rapid organic conversion simply speeds up the natural process of decomposing organic material, and by accelerating the decomposition process the ROC is able to capture the energy that is always released, but is lost, during natural decomposition.

Rapid Organic Conversion is an advanced, self sustaining technology which not only eliminates all carbon based waste more efficiently, more economically and in a more environmentally friendly manner than other current methodologies; it also efficiently converts the waste to high grade thermal energy.

Rapid Organic Conversion is an advanced, self sustaining technology which not only eliminates all carbon based waste more efficiently, more economically and in a more environmentally friendly manner than other current methodologies; it also efficiently converts the waste to high grade thermal energy.

Rapid Organic Conversion is a robust, two stage system. First self-generated, thermal energy transforms all carbon based feedstock into organic gasses. Temperature in this first stage is in the range of 850 C. The first stage process does not, however, involve incineration – no combustion of the feedstock occurs.

The gasses generated from the first stage are completely destroyed in the second stage, a high temperature, flameless oxidation chamber.Temperature in the second stage is in the range of 1400 C. High temperatures are maintained for at least two seconds to achieve maximum destruction of furans, dioxins, and Poly-Aromatic Hydrocarbons (PAH) as well as any pathogens that may be in the product gas stream.

ROC plants are automated for continuous and unattended operation, except for inspection and maintenance shutdowns.

EXECUTIVE DOWNLOAD

EXECUTIVE DOWNLOAD